Home

Centenary Celebrations

Centenary CelebrationsCentenary Celebrations

Admissions

Admissions Academics

Academics Student Life

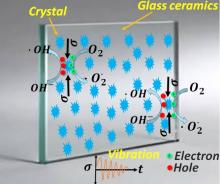

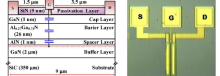

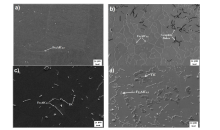

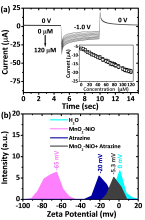

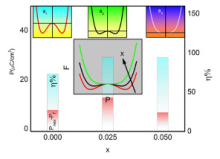

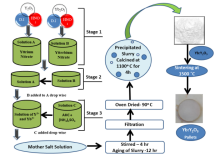

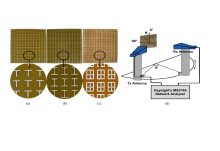

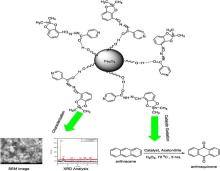

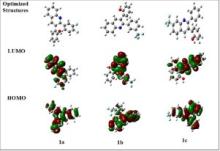

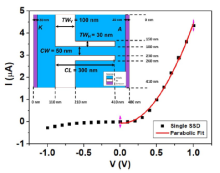

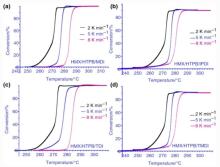

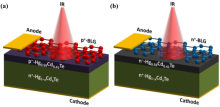

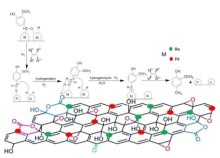

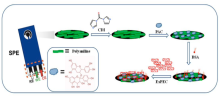

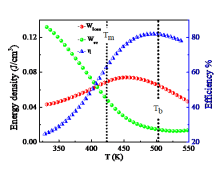

Student Life| Abstract | Advanced polycrystalline ceramics such as Y2O3, YAG are gaining importance on development of light-emitting diodes, infrared detectors, solid-state lasers, etc. The physical properties of these materials are dependent on variety of dopant concentrations. These materials such as Y2O3 could be synthesised along with Rare Earth Elements such Nd, Er, Yb etc using co-precipitation method. These synthesised samples could be tested by X-ray diffraction patterns confirm the presence of cubic phase for pure Y2O3 nanoparticles and mixed phase (cubic + monoclinic) when doped REE-Y2O3 nanoparticles. One of our recent studies of Yb doped-Y2O3 shows average crystallite size is found in the range 71 to 31 nm and lattice strain 1 × 10−4 to-5 × 10−4 calculated using Debye-Scherrer formula and Willimission-Hall plot. The crystallite size decrease with dopant concentration upto x = 0.10 and material is found to exhibit compressive lattice strain. Field-emission scanning electron microscopy shows agglomerated nanoparticles. The Fourier-transform infrared spectroscopy confirms the presence of metal oxide functional groups (Y-O and Yb-O) and vibrational bands corresponding to O-H vibration, C-O bending, and stretching modes in the samples. The band gap energy (Eg) is found to decrease from 5.14 eV for x = 0.0 to 3.60 eV for x = 0.14 composition. The photolumincence spectra show characteristic blue and green emission at 486 nm for x = 0.10 and 525 nm for x = 0.0, respectively. The frequency-dependent dielectric studies confirm the enhancement in dielectric constant with increase in Yb doping. These structural, morphological, optical, and electrical properties of Yb:Y2O3 nanoparticles are helpful for selecting this material as an appropriate candidate for laser host material for medical imaging and display devices applications. |

| Faculty |

Dr. Jagmohan Datt Sharma

|

|

jdsharma@pec.edu.in

|

|

| More Information |

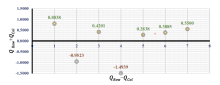

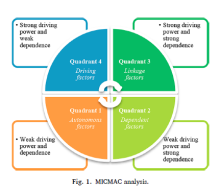

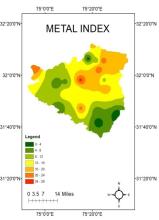

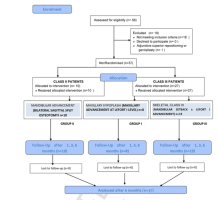

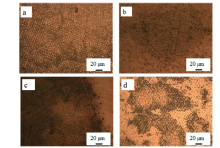

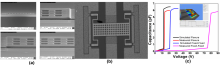

| Abstract | High entropy alloys are part of a novel area of metallurgy concerning alloys containing at least five elements with an atomic percentage ranging from 5 at% to 35 at%. The interest arises as for plenty of compositions, the formation of simple solid solutions gives rise to promising properties, pertaining their use in different fields such as structural, nuclear, automotive and aerospace industries. The main objective of this study was to synthesize CoCrFeNi1.75-xTi0.25+x(x = 0, 0.05, 0.15, 0.25) nonequiatomic, single-phase, high entropy alloys (HEAs) based on the multi-component Co-Cr-Fe-Ni-Ti system were produced by melting route in vacuum arc furnace. The characterization of newly developed HEAs was carried out using X-Ray Diffraction (XRD) and Optical Microscopy. XRD and optical microscopy confirmed the formation of single phase Ni(CoCrFeTi) FCC alloys system and dendritic structure respectively. Electrochemical workstation was used to test the corrosion behaviour of newly developed High entropy alloys in 3.5 wt% NaCl and 0.5M H2SO4 aqueous solution at room temperature. The corrosion current density (Icorr) of the alloys decreased with the increase of Ti content. When the Ti content increased from 5 at% to 10 at% the value of (Icorr) decreased from 0.423 μA to 0.270 μA in 3.5 wt% NaCl and from 21.42 μA to 16.84 μA in 0.5M H2SO4 aqueous solution, respectively. |

| Faculty |

Suresh Chand

|

|

sureshchand@pec.edu.in

|

|

| Collaborations | Indian Institute of Technology Ropar, India |

| More Information |

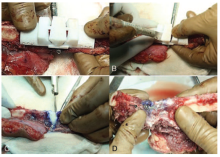

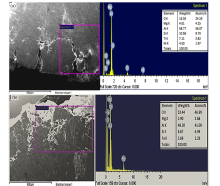

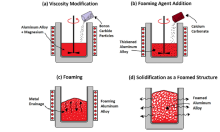

| Abstract | Corrosion behavior of FeAl-based alloys containing carbon produced through arc melting in argon atmosphere has been studied at 500 oC to 700 oC. The samples were tested in the aggressive environment of molten salts (80% V2O5/20% Na2SO4). The corrosion behavior was observed by weight change method and the layer products formed were examined by using X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS). The different phase components were observed in the surface layer after the test in Fe-22Al alloy. A protective Al2O3 layer was confirmed for Fe-22Al alloy containing carbon only. However, an additional TiO layer was also observed in Fe-22Al alloy containing carbon with Ti addition. The microstructural and XRD examinations revealed that this additional TiO layer protects better against penetration of corrosive media. The corrosion resistance behavior of FeAl-based alloys was addressed on the basis of microstructural evidence. |

| Faculty |

Suresh Chand

|

|

sureshchand@pec.edu.in

|

|

| Collaborations | IIT Roorkee, Panjab University Chandigarh, GLA University Mathura , Lovely Professional University Kapurthala |

| More Information |

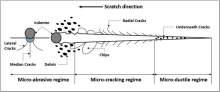

| Abstract | Owing to superior properties, i.e. high hardness, high wear resistance, and weight reduction of transparent ceramics (TCs) over glasses. TCs have shown promising tribological potential for applications such as face shields, explosive ordnance visors, windows for aircraft, spacecraft and, re-entry vehicles, electromagnetic windows, laser igniter windows, screens for smartphones and more. Researchers globally have been attracted to explore more about TCs, considering the tremendously increasing demand over different other transparent materials. The optical quality of TCs is mostly characterized by the in-line transmittance, and the effect of various processing parameters on transmittance has already been studied by various researchers. In this review, the current research progress regarding tribological performance of TCs is compiled. TCs with potential in tribological applications include MgAl2O4, Al2O3, AlON, Lu2O3, c-BN, Y2O3, Si3N4, and SiAlON. The relevant strategies to improve the tribological properties, including microstructures and mechanical properties are comprehensively discussed. |

| Faculty |

Dr. Sandan Kumar Sharma

|

|

sandan@pec.edu.in

|

|

| Collaborations | Institute of Science and Technology for Ceramics, National Research Council (CNR ISTEC), Italy |

| More Information |

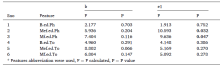

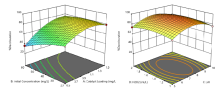

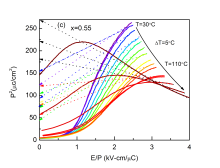

| Abstract | Today's machine components have more power, so researchers have to engineer materials that can withstand high-speed dry sliding stress. Consequently, this study examined dry sliding wear in an Austempered ductile iron (ADI) with fine ausferrite microstructure and low retained austenite. In addition, a chrome steel counterbody ball with a hardness of 60 HRC was evaluated. The wear rate, coefficient of friction and wear mechanisms were investigated. Two friction and wear regimes were identified. In the first regime of wear, wear rate increases from 21.68 to 36.29 x 10-6 mm3/Nm at low pressure; however, with high pressure, it decreases from 36.29 to 17.06 x 10-6 mm3/Nm. In second regime, at higher speed range, wear rate decreased from 17.68 to 3.11 x 10-6 mm3/Nm with applied pressure range. This behaviour well explained by the strain hardening of filmy austenite, causing compressive stress development in the neighbourhood, resulting in ADI becoming tougher at higher pressures and speeds in response. |

| Faculty |

Dr. Sandan Kumar Sharma

Dr. Pavol Hvizdoš

Dr. Michael J. Reece

Dr. Salvatore Grasso E-mail addresses

|

|

sandan@pec.edu.in

|

|

| Collaborations | Queen Mary University of London, London, UK and Slovak Academy of Sciences, Slovakia |

| More Information |