Innovations in Electro Chemical Discharge Machining Process through Electrolyte Stirring and Tool Rotations

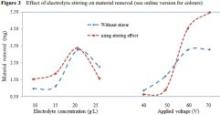

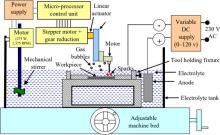

| Abstract | Electro chemical discharge machining (ECDM) process is gaining considerable importance in micro-machining of non-conductive and brittle materials like glass and ceramics. Recently it has undergone some innovations in the form of hybrid and variant processes, which have been reviewed and discussed in this paper. To further aid developments, an innovative hybrid process combining electrolyte-stirring and tool-rotation effect has been experimented and reported in this paper. The study was carried out in a phased manner on an in-house fabricated setup using Taguchi's orthogonal array L18. The experimental results illustrate an improvement in the process as compared to normal ECDM (without using electrolyte stirring and tool rotations). The optimum value for material removal was 1.282 mg/min and surface finish (Ra) was 0.4 μm. |

| Faculty |

Dr. Chandrashekhar Jawalkar

|

|

csjawalkar@pec.edu.in

|

|

| More Information | For more information: http://dx.doi.org/10.1504/IJMMM.2020.111354 |